|

|

| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90 days after all the technical requirements are confirmed |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets/yr |

PP Thick Plastic Board Making Machine Extrusion Line

1. Information of PP thick plate extrusion line

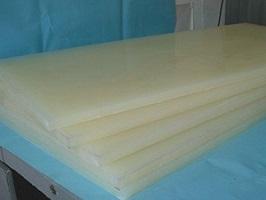

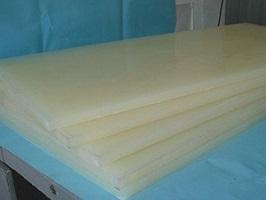

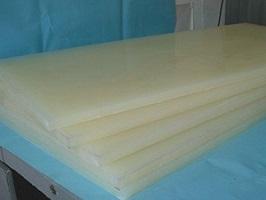

2000mm wide PP thick plate extrusion line is the most stable production line newly developed by Gwell and ahead of its peers. We use an extruder to extrude PP thick plates extrusion line. PP plates are generally white, and different color masterbatches can be added to produce other colors according to user requirements. The technological process is:

formula ---mixing ---extrusion - shaping - traction - cutting - unloading.

Gwell Intelligent Equipment Co., Ltd. is a professional enterprise engaged in the research, production, and sales of plastic machinery. The PP thick plate production equipment is one of their core products, which utilizes advanced technology and high-quality materials to effectively produce high-quality PP thick plates.

The equipment features the following main characteristics:

1. High automation: The equipment adopts advanced automation control systems, enabling automated production processes to greatly improve production efficiency and product quality.

2. Strong stability: The equipment is designed with a stable and reliable structure, along with precise processing techniques, ensuring stable operation, reduced failure rate, and enhanced production efficiency.

3. Versatility: The equipment possesses multiple functions, allowing flexibility to meet different production demands such as PP thick plate production, cutting, and molding.

4. Energy-saving and environmentally friendly: Advanced energy-saving technology is employed in the equipment, resulting in reduced energy consumption and minimized emissions of waste gases and wastewater, meeting environmental requirements.

5. High-quality products: The equipment produces PP thick plates with outstanding performance and quality. These plates exhibit excellent heat resistance, acid-alkali resistance, corrosion resistance, and find wide applications in the fields of construction, chemical industry, electronics, and more.

In summary, the PP thick plate production equipment produced by Gwell Intelligent Equipment Co., Ltd. in Suzhou is a powerful, stable, efficient, and energy-saving device suitable for various PP thick plate production needs.

(1) Put the mixed material into the feeder;

(2) The material gets heated and melt in the extruder;

(3) The melt material flows into the mould to form as the polyethylene plate

(4) After pass through the cooling brackets and haul-off unit, the board will finally be cut into pieces of products.

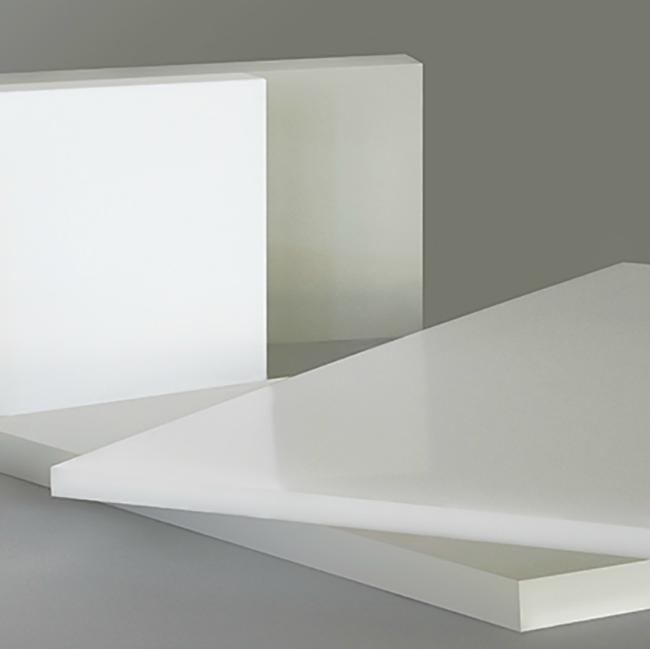

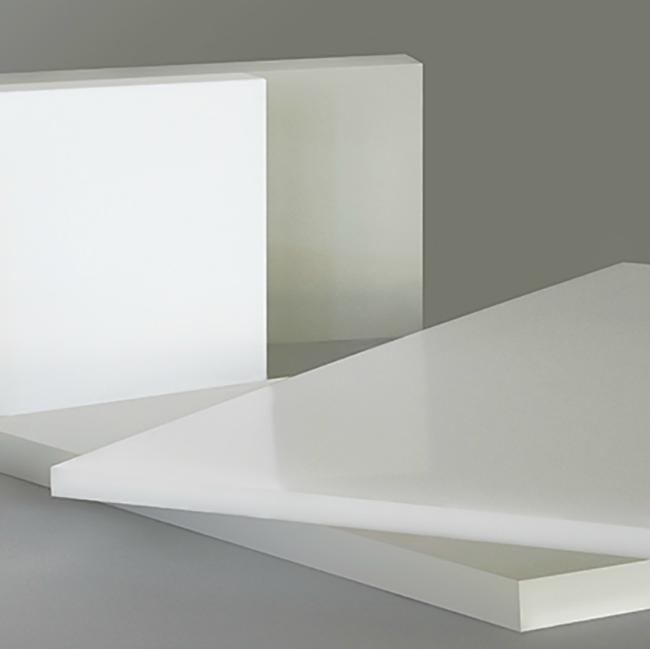

2. Information of PP thick board

1. It has moisture resistance, strong corrosion resistance, strong acid and alkali resistance, rigid plastic combination of the template, high strength, light weight, high impact strength, can be sawed, planed, nailed, cold and high temperature.

2. It has high strength, strong toughness, impact resistance, strong elasticity, and is not easy to be deformed, thereby greatly increasing the turnover and use times of the template.

3. Light weight, complete specifications, lightweight support and disassembly, safe and reliable construction operation and handling, low labor intensity, and high construction efficiency.

4. It can be used simultaneously with various material boards such as wood (bamboo) plywood.

5. After testing, the normal use times of this template can be used more than 50 times, which can greatly reduce the construction cost, and the used template can be recovered after use, and the cost saving is more substantial, which is beneficial to the development of the template leasing industry.

6. There is no need to apply mold release agent during use, which is easy to clean and maintain, thus reducing the cost of template cleaning and maintenance.

7. The surface is smooth and clean, with good peelability from concrete and easy demoulding, which can greatly speed up the construction progress and help realize fair-faced concrete.

8. If the template is damaged, it can be recycled, regenerated, and reduce the pollution of waste to the environment. It is in line with the basic national policy of creating a conservation-oriented society. The plastic template has the common use of conventional building templates and more features than conventional templates.

3. Models of extrusion line:

| Extruder Specification | GWS120 Single screw extruder | GWP75 Twin screw extruder | GWP85 Twin screw extruder |

| Suitable Material | ABS, PP, HDPE, PVDF | ||

| Thickness of Product | 3mm-30mm | 3mm-30mm | 3mm-30mm |

| Width of Product | 800mm - 1000mm | 1000mm - 1500mm | 1200mm - 2000mm |

| Output | 300kg/h-400kg/h | 400kg/h-500kg/h | 500kg/h-600kg/h |

|

|

| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90 days after all the technical requirements are confirmed |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets/yr |

PP Thick Plastic Board Making Machine Extrusion Line

1. Information of PP thick plate extrusion line

2000mm wide PP thick plate extrusion line is the most stable production line newly developed by Gwell and ahead of its peers. We use an extruder to extrude PP thick plates extrusion line. PP plates are generally white, and different color masterbatches can be added to produce other colors according to user requirements. The technological process is:

formula ---mixing ---extrusion - shaping - traction - cutting - unloading.

Gwell Intelligent Equipment Co., Ltd. is a professional enterprise engaged in the research, production, and sales of plastic machinery. The PP thick plate production equipment is one of their core products, which utilizes advanced technology and high-quality materials to effectively produce high-quality PP thick plates.

The equipment features the following main characteristics:

1. High automation: The equipment adopts advanced automation control systems, enabling automated production processes to greatly improve production efficiency and product quality.

2. Strong stability: The equipment is designed with a stable and reliable structure, along with precise processing techniques, ensuring stable operation, reduced failure rate, and enhanced production efficiency.

3. Versatility: The equipment possesses multiple functions, allowing flexibility to meet different production demands such as PP thick plate production, cutting, and molding.

4. Energy-saving and environmentally friendly: Advanced energy-saving technology is employed in the equipment, resulting in reduced energy consumption and minimized emissions of waste gases and wastewater, meeting environmental requirements.

5. High-quality products: The equipment produces PP thick plates with outstanding performance and quality. These plates exhibit excellent heat resistance, acid-alkali resistance, corrosion resistance, and find wide applications in the fields of construction, chemical industry, electronics, and more.

In summary, the PP thick plate production equipment produced by Gwell Intelligent Equipment Co., Ltd. in Suzhou is a powerful, stable, efficient, and energy-saving device suitable for various PP thick plate production needs.

(1) Put the mixed material into the feeder;

(2) The material gets heated and melt in the extruder;

(3) The melt material flows into the mould to form as the polyethylene plate

(4) After pass through the cooling brackets and haul-off unit, the board will finally be cut into pieces of products.

2. Information of PP thick board

1. It has moisture resistance, strong corrosion resistance, strong acid and alkali resistance, rigid plastic combination of the template, high strength, light weight, high impact strength, can be sawed, planed, nailed, cold and high temperature.

2. It has high strength, strong toughness, impact resistance, strong elasticity, and is not easy to be deformed, thereby greatly increasing the turnover and use times of the template.

3. Light weight, complete specifications, lightweight support and disassembly, safe and reliable construction operation and handling, low labor intensity, and high construction efficiency.

4. It can be used simultaneously with various material boards such as wood (bamboo) plywood.

5. After testing, the normal use times of this template can be used more than 50 times, which can greatly reduce the construction cost, and the used template can be recovered after use, and the cost saving is more substantial, which is beneficial to the development of the template leasing industry.

6. There is no need to apply mold release agent during use, which is easy to clean and maintain, thus reducing the cost of template cleaning and maintenance.

7. The surface is smooth and clean, with good peelability from concrete and easy demoulding, which can greatly speed up the construction progress and help realize fair-faced concrete.

8. If the template is damaged, it can be recycled, regenerated, and reduce the pollution of waste to the environment. It is in line with the basic national policy of creating a conservation-oriented society. The plastic template has the common use of conventional building templates and more features than conventional templates.

3. Models of extrusion line:

| Extruder Specification | GWS120 Single screw extruder | GWP75 Twin screw extruder | GWP85 Twin screw extruder |

| Suitable Material | ABS, PP, HDPE, PVDF | ||

| Thickness of Product | 3mm-30mm | 3mm-30mm | 3mm-30mm |

| Width of Product | 800mm - 1000mm | 1000mm - 1500mm | 1200mm - 2000mm |

| Output | 300kg/h-400kg/h | 400kg/h-500kg/h | 500kg/h-600kg/h |