| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90 days after receiving the down payment |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets per year |

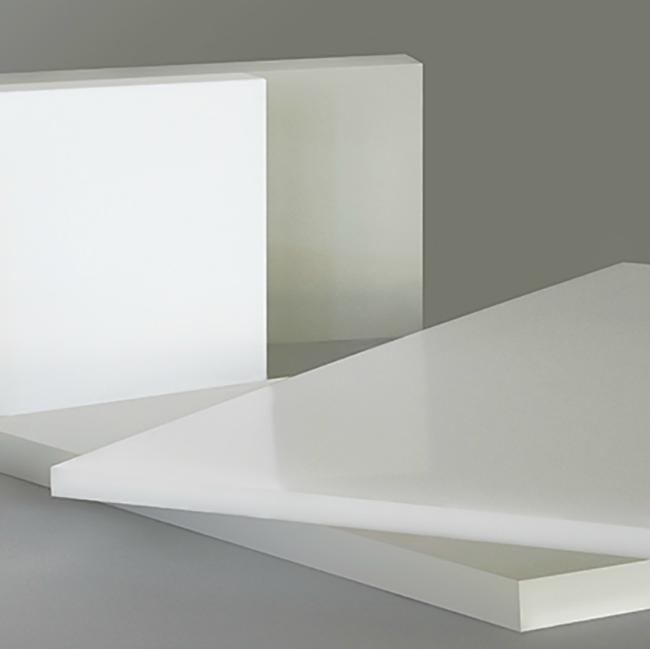

PVDF Board Making Machine PVDF Thick Sheet Production Line Single Screw Extruder

Description of PVDF Board Making Machine:

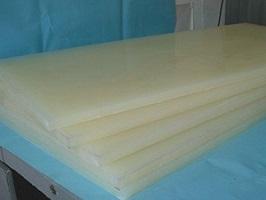

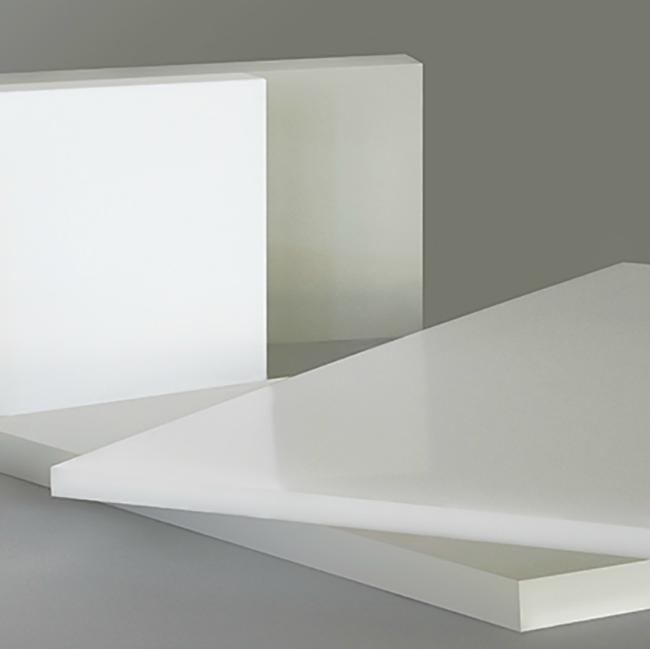

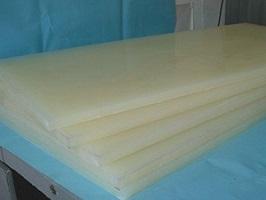

PVDF board making machine: PVDF board making machine is a pure plate formed by high temperature extrusion with polyvinylidene fluoride resin. The extrusion process does not contain additives (such as uv stabilizer, heat stabilizer, softener, lubricant or flame retardant). It is widely used in petrochemical, electric power, metallurgy, papermaking, textile, pharmaceutical and atomic energy industries and many other industrial fields, especially suitable for pure water system and semiconductor industry in the transmission of pure chemical reagent.

PPVDF board making machine, transparent plate production line: hard PVDF board making machine is widely used in chemical industry, petroleum, electroplating, water purification treatment equipment, environmental protection equipment, mines, medical electronics, communications, anti-corrosion containers, equipment electrical protection cover, light box, advertising decoration and other industries.

Specification of PVDF Board Making Machine:

| Extruder Specification | Single screw extruder GWS120 | Single screw extruder GWS150 | Single screw extruder GWS180 | Conical twin screw extruder GWP80/156 |

| Suitable Material | ABS, PP, HDPE, PVDF | ABS, PP, HDPE, PVDF | ABS, PP, HDPE, PVDF | PVC |

| Thickness of Product | 3mm-50mm | 3mm-50mm | 3mm-50mm | 3mm-30mm |

| Width of Product | 1200mm | 1800mm | 2000mm | 1220mm |

| Output | 300kg/h-400kg/h | 450kg/h-550kg/h | 500kg/h-700kg/h | 350kg/h-450kg/h |

Introduce of company:

Gwell Machinery is a high-tech enterprise, committed to providing customers with plastic sheet, board, film and other extrusion lines. Gwell can provide turnkey projects, such as stone paper project, EVA solar film project, PP building formwork equipment, CPP cast film project, etc. Gwell has a strong technical equipment strength and key capacity, committed to high-end product development, international market development. “Realize customer value" is the company's long-term business philosophy.

| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90 days after receiving the down payment |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets per year |

PVDF Board Making Machine PVDF Thick Sheet Production Line Single Screw Extruder

Description of PVDF Board Making Machine:

PVDF board making machine: PVDF board making machine is a pure plate formed by high temperature extrusion with polyvinylidene fluoride resin. The extrusion process does not contain additives (such as uv stabilizer, heat stabilizer, softener, lubricant or flame retardant). It is widely used in petrochemical, electric power, metallurgy, papermaking, textile, pharmaceutical and atomic energy industries and many other industrial fields, especially suitable for pure water system and semiconductor industry in the transmission of pure chemical reagent.

PPVDF board making machine, transparent plate production line: hard PVDF board making machine is widely used in chemical industry, petroleum, electroplating, water purification treatment equipment, environmental protection equipment, mines, medical electronics, communications, anti-corrosion containers, equipment electrical protection cover, light box, advertising decoration and other industries.

Specification of PVDF Board Making Machine:

| Extruder Specification | Single screw extruder GWS120 | Single screw extruder GWS150 | Single screw extruder GWS180 | Conical twin screw extruder GWP80/156 |

| Suitable Material | ABS, PP, HDPE, PVDF | ABS, PP, HDPE, PVDF | ABS, PP, HDPE, PVDF | PVC |

| Thickness of Product | 3mm-50mm | 3mm-50mm | 3mm-50mm | 3mm-30mm |

| Width of Product | 1200mm | 1800mm | 2000mm | 1220mm |

| Output | 300kg/h-400kg/h | 450kg/h-550kg/h | 500kg/h-700kg/h | 350kg/h-450kg/h |

Introduce of company:

Gwell Machinery is a high-tech enterprise, committed to providing customers with plastic sheet, board, film and other extrusion lines. Gwell can provide turnkey projects, such as stone paper project, EVA solar film project, PP building formwork equipment, CPP cast film project, etc. Gwell has a strong technical equipment strength and key capacity, committed to high-end product development, international market development. “Realize customer value" is the company's long-term business philosophy.