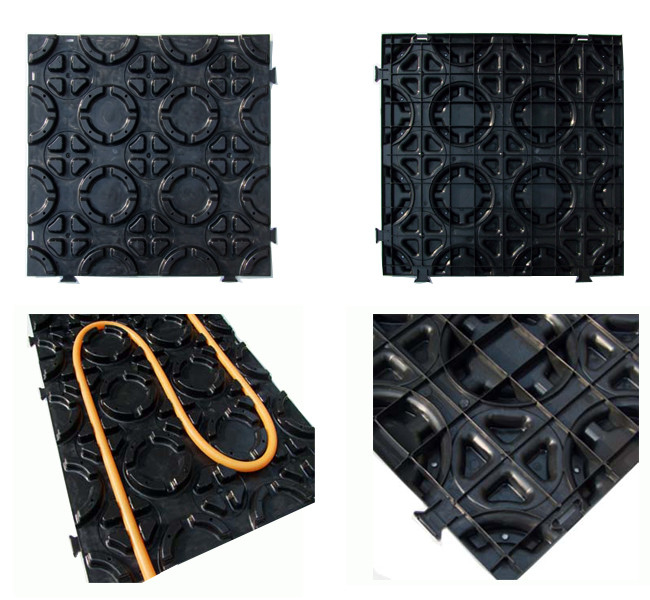

The Plastic Hot Water Radiant Floor Heating Module production line is a cutting-edge manufacturing system engineered to produce high-quality radiant floor heating modules. At the heart of this production line is the extruder, featuring a high-performance single screw configuration. This critical component enables precise control over the extrusion process, ensuring the consistent production of heating modules with exceptional quality.

One of the key strengths of this production line is its customization capabilities, allowing for seamless adaptation to the specific requirements of customers. From output thickness to width, each aspect of the production process can be tailored to meet the unique demands of individual customers, enhancing flexibility and enabling the production of modules that align precisely with desired specifications.

With its advanced extrusion technology and customizable features, the Plastic Hot Water Radiant Floor Heating Module production line stands as a versatile and reliable solution for manufacturing top-of-the-line heating modules while accommodating the diverse needs of customers.

This state-of-the-art production line is designed to meet the highest industry standards, delivering consistent and reliable performance to fulfill the demands of modern manufacturing. By integrating advanced extrusion technology with customer-driven customization, this production line offers a seamless and efficient manufacturing process for plastic hot water radiant floor heating modules.

Furthermore, the extruder, equipped with a single screw, plays a pivotal role in ensuring the precision and uniformity of the heating module production. Its adaptable nature enables the accommodation of varying output specifications, allowing for a tailored approach that meets the specific needs of customers.

In summary, the Plastic Hot Water Radiant Floor Heating Module production line represents a technological advancement in the manufacturing of heating modules, offering both quality and customization to address the diverse requirements of customers in the industry.