| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90-100 days after all the technical requirements are confirmed |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets/year |

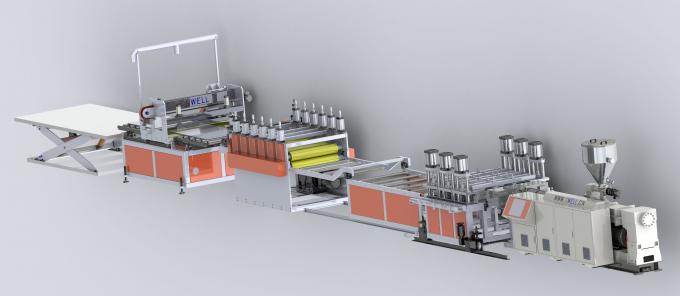

Pvc Foam Board Extrusion Line Pvc floor production machine

1. Introduction of PVC wood plastic floor production equipment

The unit has a compact structure and superior performance.

The screw and barrel are optimized and processed with high-performance alloy steel, so that the whole machine has the advantages of uniform plasticization, stable extrusion, high output, and long life. The main barrel is heated by cast aluminum heater, cooled by air, and the temperature is controlled by precision electronic control instrument. The precise shaping and calendering device, through its good adjustment function, makes the plate shape excellent. The cutting part adopts a fixed-length cutting device to ensure the precise length of the plate.

The production process of PVC floor production line of GWELL company is:

(1) The raw material will be automatic fed into high-speed mixing,

(2) Then it is automatically fed into the twin-screw extruder,

(3) Then the melt material will be extruded out from the T-die which is special for plate,

(4) After going through the T-die, the plate will be formed by the calibration table and cooled by cooling brackets,

(5) Then the board will be through the edge trimming unit, traction unit, automatic cutting unit, automatic lifting unit, roller conveyor, etc.

2. Features of PVC floor extrusion line

The features of pvc floor: light weight, sound absorption, waterproof, moisture-proof, insect-proof, termite proof, high environmental protection, no pollution, recyclable, high fire resistance, effective flame retardant, low transportation cost, simple and convenient installation.

3. Machine configuration:

| Type of extruder | Conical twin-screw extruder GWC80/156-955 | Conical twin-screw extruder GWC92/188-1200 | Conical twin-screw extruder GWC80/156-YF350 |

| Width of product | 955mm | 1200mm | Profile 200mm-350mm |

| Thickness of product | 3mm-6mm | 3mm-6mm | 5mm-20mm |

| Output | 350kg/h-400kg/h | 500kg/h-600kg/h | 300kg/h-350kg/h |

4.Introduce of PVC floor extrusion line

Wood-plastic Composites (PVC) is a kind of new composite material which is booming at home and abroad in recent years. With the continuous development of new environmental protection industry, people have higher and higher requirements on environmental protection. As a new environmental protection material, wood-plastic has been applied more and more widely in the field of home decoration. Our company designed PVC floor extrusion production line for the development of the floor special equipment, mainly used for the wood-plastic floor with width 955mm, thickness of 3-5mm.

| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90-100 days after all the technical requirements are confirmed |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets/year |

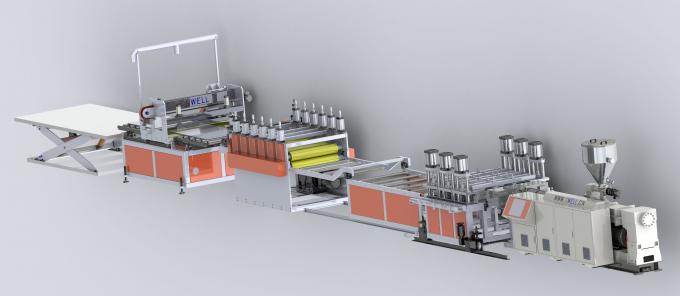

Pvc Foam Board Extrusion Line Pvc floor production machine

1. Introduction of PVC wood plastic floor production equipment

The unit has a compact structure and superior performance.

The screw and barrel are optimized and processed with high-performance alloy steel, so that the whole machine has the advantages of uniform plasticization, stable extrusion, high output, and long life. The main barrel is heated by cast aluminum heater, cooled by air, and the temperature is controlled by precision electronic control instrument. The precise shaping and calendering device, through its good adjustment function, makes the plate shape excellent. The cutting part adopts a fixed-length cutting device to ensure the precise length of the plate.

The production process of PVC floor production line of GWELL company is:

(1) The raw material will be automatic fed into high-speed mixing,

(2) Then it is automatically fed into the twin-screw extruder,

(3) Then the melt material will be extruded out from the T-die which is special for plate,

(4) After going through the T-die, the plate will be formed by the calibration table and cooled by cooling brackets,

(5) Then the board will be through the edge trimming unit, traction unit, automatic cutting unit, automatic lifting unit, roller conveyor, etc.

2. Features of PVC floor extrusion line

The features of pvc floor: light weight, sound absorption, waterproof, moisture-proof, insect-proof, termite proof, high environmental protection, no pollution, recyclable, high fire resistance, effective flame retardant, low transportation cost, simple and convenient installation.

3. Machine configuration:

| Type of extruder | Conical twin-screw extruder GWC80/156-955 | Conical twin-screw extruder GWC92/188-1200 | Conical twin-screw extruder GWC80/156-YF350 |

| Width of product | 955mm | 1200mm | Profile 200mm-350mm |

| Thickness of product | 3mm-6mm | 3mm-6mm | 5mm-20mm |

| Output | 350kg/h-400kg/h | 500kg/h-600kg/h | 300kg/h-350kg/h |

4.Introduce of PVC floor extrusion line

Wood-plastic Composites (PVC) is a kind of new composite material which is booming at home and abroad in recent years. With the continuous development of new environmental protection industry, people have higher and higher requirements on environmental protection. As a new environmental protection material, wood-plastic has been applied more and more widely in the field of home decoration. Our company designed PVC floor extrusion production line for the development of the floor special equipment, mainly used for the wood-plastic floor with width 955mm, thickness of 3-5mm.