|

|

| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90 days after all the technical requirements are confirmed |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets/yr |

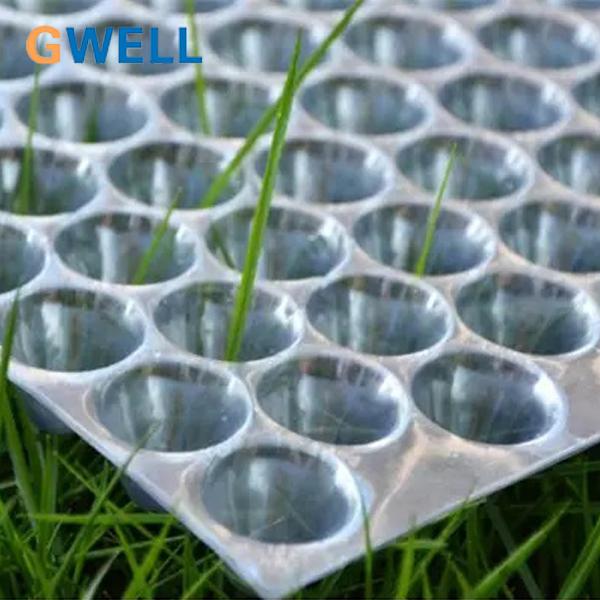

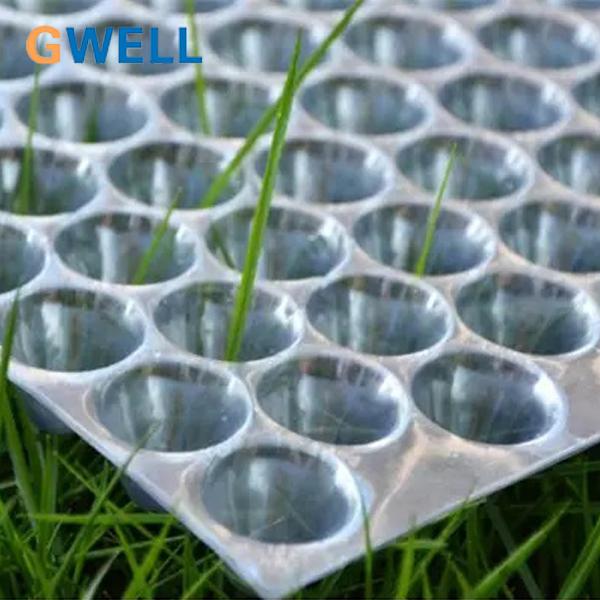

Recycled PET Sheet Extrusion Line For White Or Black Farm Seeding Tray

Recycled PET Sheet Extrusion Line For Farm Seeding Tray

1. Introduction of PET sheet making machine for seeding tray

Since the PET material that customers will use to produce seeding tray is mostly recycled PET and PET scraps, we will design the production line to be twin-screw designed. It can process 100% recycled PET and safe the step of cystallization and drying. By reducing this steps, it helps save a lot of time before production and save the power of this step. We have several different designs of the twin-screw production lines, mostly the difference is focused on the production capacity. And the sheet width can be customized as well.

If you are interested, please feel free to contact us.

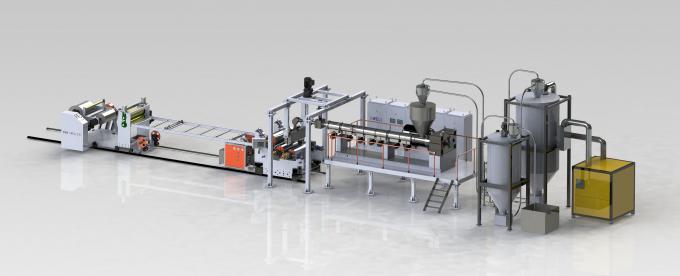

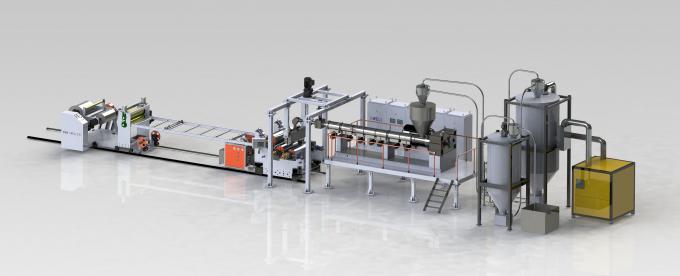

2. Introduction of PET seeding tray sheet twin-screw exhaust extrusion line:

APET, PETG, CPET sheet twin-screw exhaust making machine is improved from PET sheet single-screw making machine. The raw material processing non-crystallization, non-drying exhaust type PET sheet unit of this making machine has the advantages of low energy consumption and high efficiency. This model is a continuous improvement and upgrade product of Gwell. It has made significant improvements to the core vacuum system. The technology upgrades from the original Roots-water ring pump set to the Roots-rotary vane pump set, which can make the vacuum reach ≤10Pa. At the same time, the PET special alloy steel thin-walled roller set is used to greatly improve the cooling efficiency, thereby increase output, improve product toughness and transparency. The operating system independently written by Gwell ensures the humanization and easy operation of the equipment.

2. Machine models of PET sheet making machine

| Type of machine | GWP75 Twin screw+GWS65 Single screw | GWP85 Twin screw+GWP52 twin screw | GWP95 Twin screw+GWP65Twin screw |

| Width of product | 800mm - 1000mm | 800mm - 1200mm | 1000mm - 1500mm |

| Thickness of product | 0.15mm - 2mm | 0.15mm - 2mm | 0.15mm - 2mm |

| Output | 300KG/H - 450KG/H | 500KG/H - 600KG/H | 800KG/H - 900KG/H |

| Type of machine | GWS90 single screw | GWS120 single screw | GWS150 single screw |

| Width of product | 600mm - 800mm | 800mm - 1200mm | 1000mm - 1500mm |

| Thickness of product | 0.15mm - 2mm | 0.15mm - 2mm | 0.15mm - 2mm |

| Output | 150KG/H - 200KG/H | 300KG/H - 400KG/H | 400KG/H - 500KG/H |

PET (Polyethylene terephthalate) extrusion line is a specialized production line used for manufacturing PET films and sheets. PET is a versatile thermoplastic polymer known for its excellent combination of mechanical, thermal, and chemical properties. It is widely used in industries such as packaging, textiles, automotive, and electrical.

Here are some key points about the PET extrusion line:

1. High-quality extrusion: The PET extrusion line is equipped with a high-performance extruder that ensures efficient and uniform melting and extrusion of the PET resin. This results in excellent film quality and consistency.

2. Precise temperature control: The extrusion line features an advanced temperature control system that allows precise adjustment of the heating and cooling zones. This ensures optimal processing conditions, resulting in films with consistent properties and thickness.

3. Multi-layer film capability: The PET extrusion line enables the production of multi-layer films with different functionalities. By incorporating multiple extruders and co-extrusion technology, it is possible to produce films with enhanced barrier properties, improved strength, or specialized surface properties.

4. Versatile film width and thickness: The PET extrusion line offers flexibility in producing films with various widths and thicknesses according to customer requirements. It can accommodate a wide range of film sizes, from thin gauge films used for packaging to thicker sheets used for industrial applications.

5. Efficient cooling and stretching system: The extrusion line includes a precise cooling and stretching system that ensures controlled cooling and precise stretching of the molten PET film to achieve the desired thickness and properties. This system helps maintain dimensional stability and control orientation.

6. Surface treatment options: The PET extrusion line can be equipped with additional surface treatment options such as corona treatment or plasma treatment. These treatments enhance the adhesion of inks, coatings, or adhesives to the PET film, enabling better printability, laminating, or bonding properties.

7. Inline quality control: The extrusion line incorporates inline monitoring and control systems for key parameters such as film thickness, transparency, and surface defects. This ensures consistent film quality and allows for real-time adjustments and troubleshooting during production.

8. Energy efficiency: The PET extrusion line is designed with energy-efficient components and technologies to minimize energy consumption and reduce operating costs. It utilizes advanced heat recovery systems and optimized heating and cooling processes.

9. Automation and advanced controls: The PET extrusion line is equipped with modern automation and control systems, including PLC touch screens and advanced control algorithms. This facilitates easy operation, monitoring, and adjustments for efficient production.

10. Sustainable production: PET extrusion lines can be designed to incorporate recycling or reclaiming systems, enabling the use of recycled PET material and contributing to a more sustainable production process.

The PET extrusion line offers reliable and efficient production of high-quality PET films and sheets, meeting the diverse needs of industries requiring PET-based materials.

|

|

| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90 days after all the technical requirements are confirmed |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets/yr |

Recycled PET Sheet Extrusion Line For White Or Black Farm Seeding Tray

Recycled PET Sheet Extrusion Line For Farm Seeding Tray

1. Introduction of PET sheet making machine for seeding tray

Since the PET material that customers will use to produce seeding tray is mostly recycled PET and PET scraps, we will design the production line to be twin-screw designed. It can process 100% recycled PET and safe the step of cystallization and drying. By reducing this steps, it helps save a lot of time before production and save the power of this step. We have several different designs of the twin-screw production lines, mostly the difference is focused on the production capacity. And the sheet width can be customized as well.

If you are interested, please feel free to contact us.

2. Introduction of PET seeding tray sheet twin-screw exhaust extrusion line:

APET, PETG, CPET sheet twin-screw exhaust making machine is improved from PET sheet single-screw making machine. The raw material processing non-crystallization, non-drying exhaust type PET sheet unit of this making machine has the advantages of low energy consumption and high efficiency. This model is a continuous improvement and upgrade product of Gwell. It has made significant improvements to the core vacuum system. The technology upgrades from the original Roots-water ring pump set to the Roots-rotary vane pump set, which can make the vacuum reach ≤10Pa. At the same time, the PET special alloy steel thin-walled roller set is used to greatly improve the cooling efficiency, thereby increase output, improve product toughness and transparency. The operating system independently written by Gwell ensures the humanization and easy operation of the equipment.

2. Machine models of PET sheet making machine

| Type of machine | GWP75 Twin screw+GWS65 Single screw | GWP85 Twin screw+GWP52 twin screw | GWP95 Twin screw+GWP65Twin screw |

| Width of product | 800mm - 1000mm | 800mm - 1200mm | 1000mm - 1500mm |

| Thickness of product | 0.15mm - 2mm | 0.15mm - 2mm | 0.15mm - 2mm |

| Output | 300KG/H - 450KG/H | 500KG/H - 600KG/H | 800KG/H - 900KG/H |

| Type of machine | GWS90 single screw | GWS120 single screw | GWS150 single screw |

| Width of product | 600mm - 800mm | 800mm - 1200mm | 1000mm - 1500mm |

| Thickness of product | 0.15mm - 2mm | 0.15mm - 2mm | 0.15mm - 2mm |

| Output | 150KG/H - 200KG/H | 300KG/H - 400KG/H | 400KG/H - 500KG/H |

PET (Polyethylene terephthalate) extrusion line is a specialized production line used for manufacturing PET films and sheets. PET is a versatile thermoplastic polymer known for its excellent combination of mechanical, thermal, and chemical properties. It is widely used in industries such as packaging, textiles, automotive, and electrical.

Here are some key points about the PET extrusion line:

1. High-quality extrusion: The PET extrusion line is equipped with a high-performance extruder that ensures efficient and uniform melting and extrusion of the PET resin. This results in excellent film quality and consistency.

2. Precise temperature control: The extrusion line features an advanced temperature control system that allows precise adjustment of the heating and cooling zones. This ensures optimal processing conditions, resulting in films with consistent properties and thickness.

3. Multi-layer film capability: The PET extrusion line enables the production of multi-layer films with different functionalities. By incorporating multiple extruders and co-extrusion technology, it is possible to produce films with enhanced barrier properties, improved strength, or specialized surface properties.

4. Versatile film width and thickness: The PET extrusion line offers flexibility in producing films with various widths and thicknesses according to customer requirements. It can accommodate a wide range of film sizes, from thin gauge films used for packaging to thicker sheets used for industrial applications.

5. Efficient cooling and stretching system: The extrusion line includes a precise cooling and stretching system that ensures controlled cooling and precise stretching of the molten PET film to achieve the desired thickness and properties. This system helps maintain dimensional stability and control orientation.

6. Surface treatment options: The PET extrusion line can be equipped with additional surface treatment options such as corona treatment or plasma treatment. These treatments enhance the adhesion of inks, coatings, or adhesives to the PET film, enabling better printability, laminating, or bonding properties.

7. Inline quality control: The extrusion line incorporates inline monitoring and control systems for key parameters such as film thickness, transparency, and surface defects. This ensures consistent film quality and allows for real-time adjustments and troubleshooting during production.

8. Energy efficiency: The PET extrusion line is designed with energy-efficient components and technologies to minimize energy consumption and reduce operating costs. It utilizes advanced heat recovery systems and optimized heating and cooling processes.

9. Automation and advanced controls: The PET extrusion line is equipped with modern automation and control systems, including PLC touch screens and advanced control algorithms. This facilitates easy operation, monitoring, and adjustments for efficient production.

10. Sustainable production: PET extrusion lines can be designed to incorporate recycling or reclaiming systems, enabling the use of recycled PET material and contributing to a more sustainable production process.

The PET extrusion line offers reliable and efficient production of high-quality PET films and sheets, meeting the diverse needs of industries requiring PET-based materials.