| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90-120 days for production cycle |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets per year |

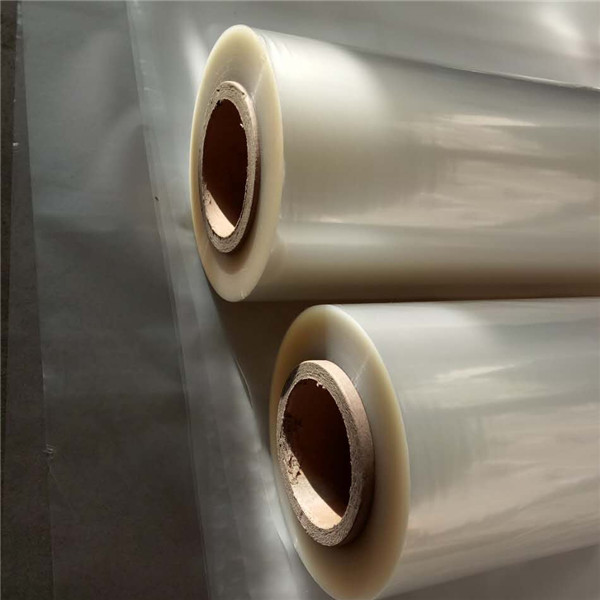

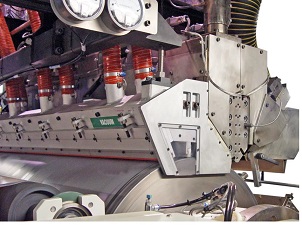

CPP CPE Cast Film make machine,Low energy consumption and high efficiency

1. Introduction of CPP/CPE cast film production machine

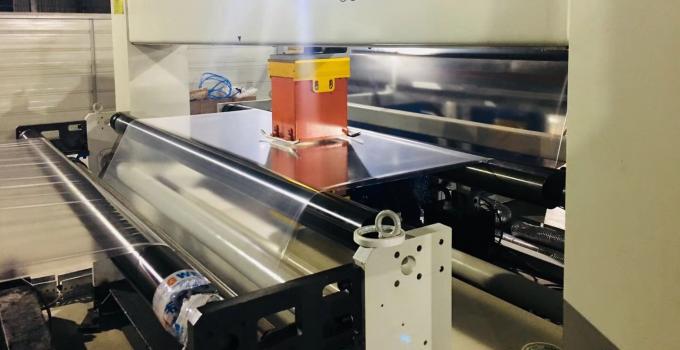

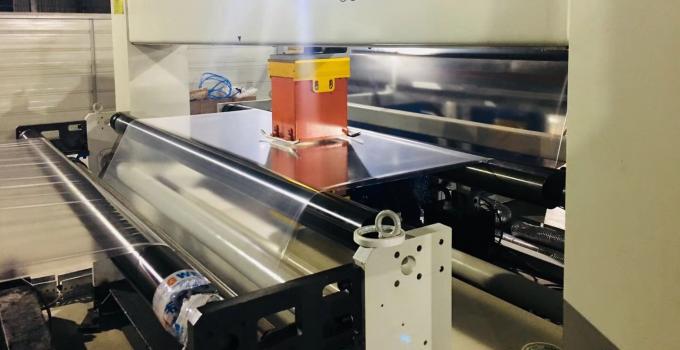

GWELL company CPP/CPE cast film extrusion line adopts the method of single-extruder or multi-extruder co-extrusion to produce single-layer or multi-layer co-extrusion film, and distributor can be used to realize the production of the maximum 7-layer film. By using metering pumps, digital precise control of material percentage can achieve the precise input of special materials and reduce the cost. Our machines have achieved a high degree of automation, saving labor costs and improving production efficiency.

(1) The screw adopts special mixing function and high plasticizing capacity design, with static mixer to ensure good plasticization, good mixing effect and high output;

(2) The automatic die head adjustment and automatic thickness gauge can be used to automatically detect the film thickness online and automatically adjust the die head;

(3) Cooperate with special cooling forming roller and special spiral flow channel design to ensure rapid cooling and shaping of the film under high output

(4) Equipped with positive pressure device and negative pressure device to ensure the shape of the film, stable size and good surface flatness

(5) The film edge material is directly recycled and reused online, which greatly reduces the production cost;

(7) Fully automatic central winding machine, equipped with imported tension controller, to precisely control the tension. With automatic roll changing and cutting functions, the operation is simple and quick.

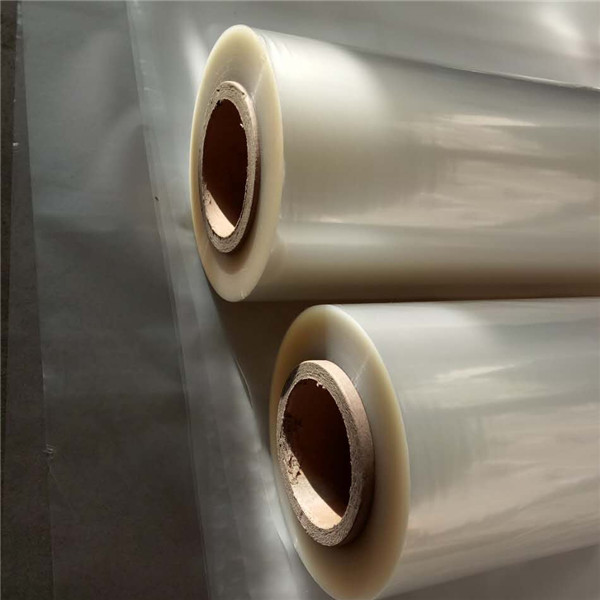

2. Application of CPP/CPE cast film

Food packaging: product packaging with higher requirements on display effect, such as bread, dry food, etc. It can be used to twist the packaging of candies and snacks, etc. After special surface treatment, it can produce metalic reflective film, to package fast food and so on.

It can also be used for packaging of retail products with higher requirements on freshness of packaging materials, such as flowers, clothing, etc. Films produced in a sterile environment can also be used in medical field.

3. Specification:

| Type of extruder | Single screw extruder GWS90/135/90 | Single screw extruder GWS100/150/100 | Single screw extruder GWS120/180/120 |

| Raw material | PP/PE | PP/PE | PP/PE |

| Width of product | 2200mm | 3500mm | 4000mm |

| Thickness of product | 0.02mm-0.1mm | 0.02mm-0.1mm | 0.02mm-0.1mm |

| Length and width of the roller | 900mm/2500mm | 900mm/4000mm | 900mm/4500mm |

| Line speed | 250m/min | 250m/min | 250m/min |

| MOQ: | 1 set |

| Price: | Negotiable |

| Standard Packaging: | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Delivery Period: | 90-120 days for production cycle |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 200 sets per year |

CPP CPE Cast Film make machine,Low energy consumption and high efficiency

1. Introduction of CPP/CPE cast film production machine

GWELL company CPP/CPE cast film extrusion line adopts the method of single-extruder or multi-extruder co-extrusion to produce single-layer or multi-layer co-extrusion film, and distributor can be used to realize the production of the maximum 7-layer film. By using metering pumps, digital precise control of material percentage can achieve the precise input of special materials and reduce the cost. Our machines have achieved a high degree of automation, saving labor costs and improving production efficiency.

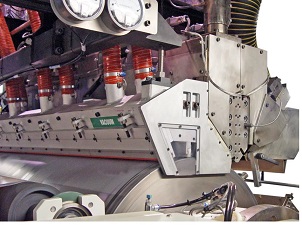

(1) The screw adopts special mixing function and high plasticizing capacity design, with static mixer to ensure good plasticization, good mixing effect and high output;

(2) The automatic die head adjustment and automatic thickness gauge can be used to automatically detect the film thickness online and automatically adjust the die head;

(3) Cooperate with special cooling forming roller and special spiral flow channel design to ensure rapid cooling and shaping of the film under high output

(4) Equipped with positive pressure device and negative pressure device to ensure the shape of the film, stable size and good surface flatness

(5) The film edge material is directly recycled and reused online, which greatly reduces the production cost;

(7) Fully automatic central winding machine, equipped with imported tension controller, to precisely control the tension. With automatic roll changing and cutting functions, the operation is simple and quick.

2. Application of CPP/CPE cast film

Food packaging: product packaging with higher requirements on display effect, such as bread, dry food, etc. It can be used to twist the packaging of candies and snacks, etc. After special surface treatment, it can produce metalic reflective film, to package fast food and so on.

It can also be used for packaging of retail products with higher requirements on freshness of packaging materials, such as flowers, clothing, etc. Films produced in a sterile environment can also be used in medical field.

3. Specification:

| Type of extruder | Single screw extruder GWS90/135/90 | Single screw extruder GWS100/150/100 | Single screw extruder GWS120/180/120 |

| Raw material | PP/PE | PP/PE | PP/PE |

| Width of product | 2200mm | 3500mm | 4000mm |

| Thickness of product | 0.02mm-0.1mm | 0.02mm-0.1mm | 0.02mm-0.1mm |

| Length and width of the roller | 900mm/2500mm | 900mm/4000mm | 900mm/4500mm |

| Line speed | 250m/min | 250m/min | 250m/min |